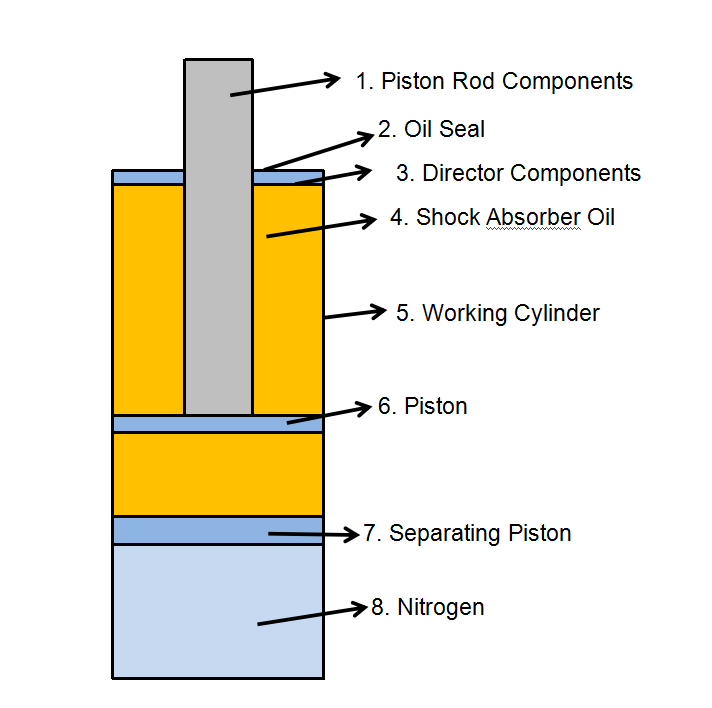

Mono tube shock absorber only has one working cylinder. And normally, the high pressure gas inside it is about 2.5Mpa. There are two pistons in the working cylinder. The piston in the rod can generate the damping forces; and the free piston can separate the oil chamber from the gas chamber within the working cylinder.

The advantages of mono tube shock absorber:

1. Zero restrictions on installation angles.

2. The shock absorber reaction in time, no empty process defects, damping force is good.

3. Because the shock absorber only has one working cylinder. When temperature increases, oil is able to release heat easy.

The disadvantages of mono tube shock absorber:

1. It requires a long size working cylinder, so it is difficult to applicate in normal passage car.

2. The high pressured gas inside the working cylinder can lead to a higher amount of stress on seals which can cause it easy damage, so it requires good oil seals.

Picture 1: The Structure of Mono Tube Shock Absorber

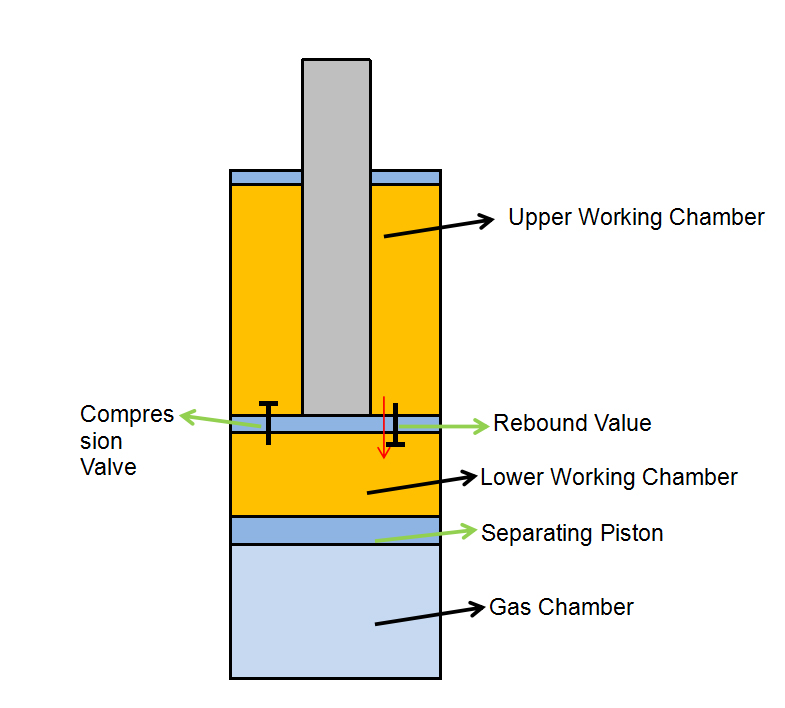

The shock absorber has three working chambers, two valves and oneseparating piston.

Three Working Chambers:

1. Upper working chamber: the upper part of the piston.

2. Lower working chamber: the lower part of the piston.

3. Gas chamber: the parts of high pressure nitrogen inside.

The Two valves include compression valve and rebound value. The separating piston is between the lower working chamber and gas chamber which separates them.

Picture 2 The working chambers and values of Mono Tube Shock absorber

1. Compression

The piston rod of shock absorber moves from upper to down according with the working cylinder. When the vehicle‘s wheels are moving close to the body of vehicle, the shock absorber is compressed, so the piston moves downward. The volume of the lower working chamber decreases, and the oil pressure of the lower working chamber increases, so the compression valve is open and the oil flows into upper working chamber. Because the piston rod occupied some space in the upper working chamber, the increased volume in upper working chamber is lesser than the decreased volume of lower working chamber; some oil pushes the separating piston downward and the volume of gas decreases, so the pressure in gas chamber increased. (See detail as the picture 3)

Picture 3 Compression Process

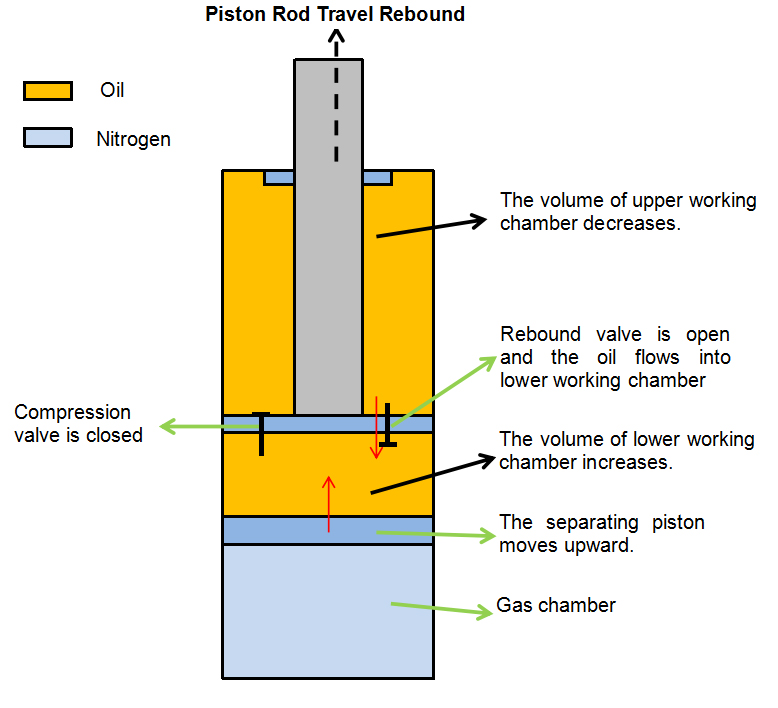

2. TENSION

The piston rod of shock absorber moves upper according with the working cylinder. When the vehicle’s wheels are moving far away the body of vehicle, the shock absorber is rebounded, so the piston moves upward. The oil pressure of the upper working chamber increases, so the compression valve is closed. The rebound valve is open and the oil flows into lower working chamber. Because one parts of piston rod is out of working cylinder, the volume of working cylinder increases, so the stress in gas chamber is higher than the lower working chamber, some gas pushes the separating piston upward and the volume of gas decreases, so the pressure in gas chamber decreased. (See detail as the picture 4)

Picture 4 Rebound Process

Post time: Jul-28-2021