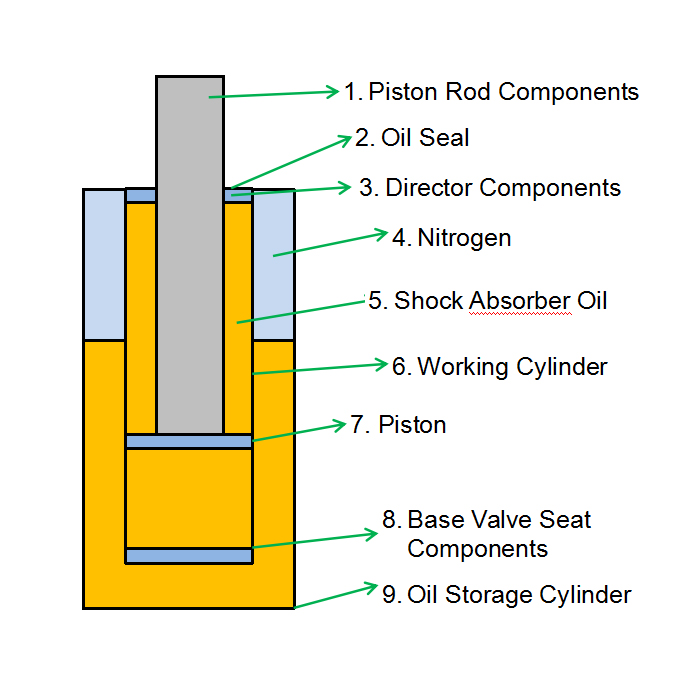

In order to know well of the twin tube shock absorber working, let first introduce the structure of it. Please see the picture 1. The structure can help us see twin tube shock absorber clearly and directly.

Picture 1 : The Structure of Twin Tube Shock Absorber

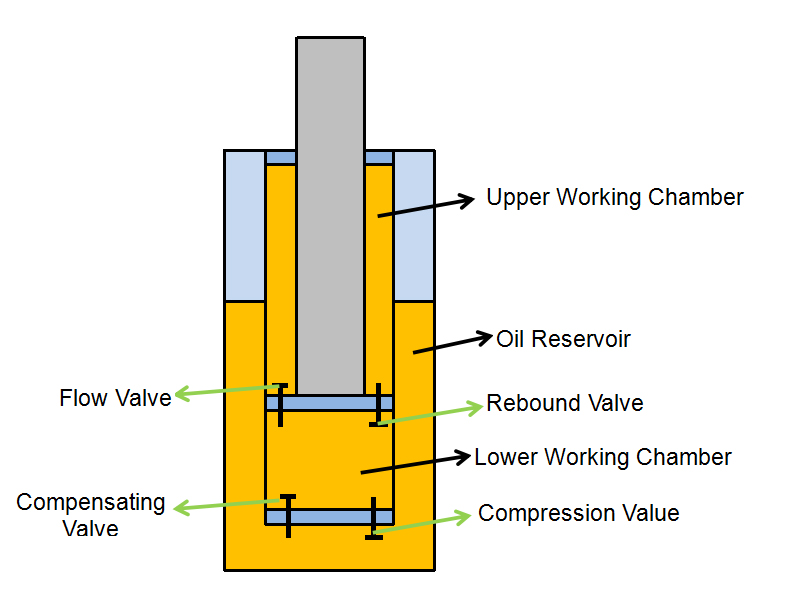

The shock absorber has three working chambers and four valves. See the details of the picture 2.

Three Working Chambers:

1. Upper working chamber: the upper part of the piston, which is also called high pressure chamber.

2. Lower working chamber: the lower part of the piston.

3. Oil reservoir: The four valves includes flow valve, rebound valve, compensating valve and compression value. The flow valve and rebound valve are installed on the piston rod; they are parts of piston rod components. The compensating valve and compression value are installed on the base valve seat; they are parts of base valve seat components.

Picture 2 : The working chambers and values of Shock absorber

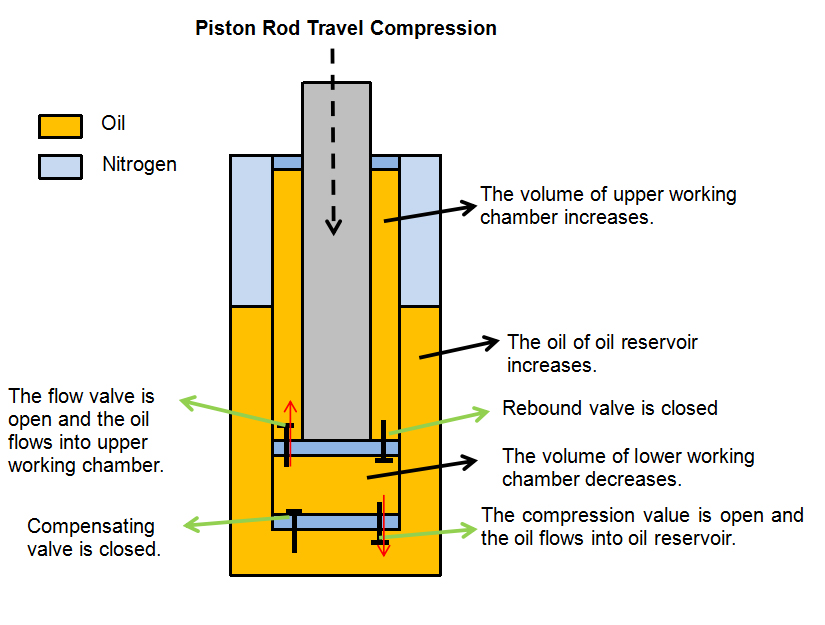

The two processes of shock absorber working:

1. Compression

The piston rod of shock absorber moves from upper to down according with the working cylinder. When the vehicle‘s wheels are moving close to the body of vehicle, the shock absorber is compressed, so the piston moves downward. The volume of the lower working chamber decreases, and the oil pressure of the lower working chamber increases, so the flow valve is open and the oil flows into upper working chamber. Because the piston rod occupied some space in the upper working chamber, the increased volume in upper working chamber is lesser than the decreased volume of lower working chamber, some oil opened compression value and flows back into oil reservoir. All the values contribute to throttle and cause damping force of the shock absorber. (See detail as the picture 3)

Picture 3: Compression Process

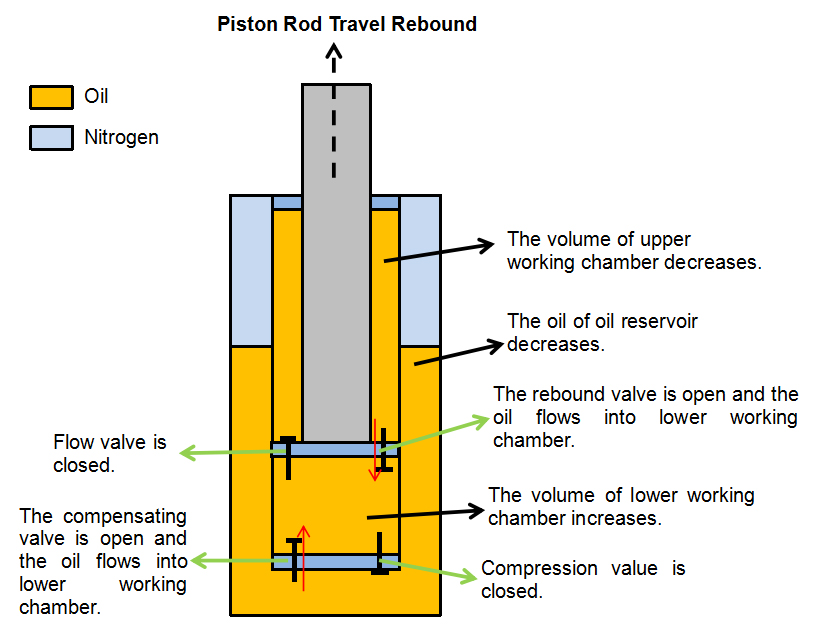

2. Rebound

The piston rod of shock absorber moves upper according with the working cylinder. When the vehicle’s wheels are moving far away the body of vehicle, the shock absorber is rebounded, so the piston moves upward. The oil pressure of the upper working chamber increases, so the flow valve is closed. The rebound valve is open and the oil flows into lower working chamber. Because one parts of piston rod is out of working cylinder, the volume of working cylinder increases, the oil in oil reservoir opened compensating valve and flows into lower working chamber. All the values contribute to throttle and cause damping force of the shock absorber. (See detail as the picture 4)

Picture 4: Rebound Process

Generally speaking, the pre-tightening force design of rebound valve is larger than that of compression valve. Under the same pressure, the cross-section of the oil flows in rebound valve is smaller than that of compression valve. So the damping force in rebound process is greater than that of in compression process (of course, it is also possible that the damping force in compression process is greater than the damping force in rebound process). This design of shock absorber can achieve the purpose of rapid shock absorption.

In fact, the shock absorber is one of energy decay process. So its action principle is based on the energy conservation law. The energy derives from the gasoline combustion process; the engine-driven vehicle shakes up and down when it runs on rough road. When the vehicle vibrates, the coil spring absorbs the vibration energy and converts it into potential energy. But the coil spring can’t consume the potential energy, it is still exists. It causes that the vehicle shakes up and down all the time. The shock absorber works to consume the energy and converts it into thermal energy; the thermal energy is absorbed by the oil and other components of shock absorber, and emitted into the atmosphere at last.

Post time: Jul-28-2021